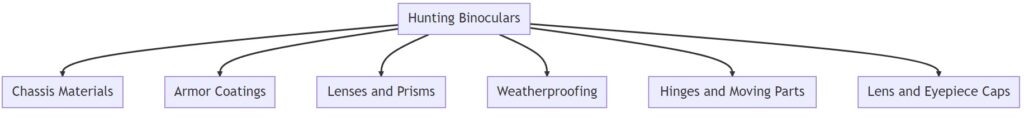

Contents

Hunting binoculars are an indispensable tool. The rugged environments and extreme conditions that hunters often encounter require binoculars that are not only optically capable but also incredibly durable. The choice of materials used in the construction of these optical instruments plays a pivotal role in determining their longevity and performance.

The materials used impact how well your binoculars withstand rough conditions. Look for magnesium alloy or polycarbonate chassis, as they offer strength without excessive weight. Durability in binocular materials ensures your gear will last for years of successful hunting adventures.

Rubber armor coatings provide grip, protection from impacts, and water resistance. High-quality glass like ED or HD ensures optical clarity and scratch resistance. Ensure your binoculars are waterproof and fog proof for all-weather reliability. Opt for brands with a strong reputation and warranties for peace of mind.

Binocular Materials: Why It Matters?

The choice of materials in binocular construction plays a fundamental role in determining the overall performance, durability, and functionality of these optical instruments. These materials impact various aspects of binocular performance and longevity:

Weight: Avid hunters often cover extensive terrain, and every ounce counts. Materials that are lightweight, yet durable, are favored to keep the overall weight of the binoculars manageable.

Strength: Hunting environments can be tough on gear. Binoculars need to withstand impacts, falls, and rough handling without compromising performance.

Weather Resistance: Exposure to the elements is inevitable. Materials should be able to resist moisture, protect against corrosion, and maintain optical clarity even in harsh weather conditions.

Optical Quality: The quality of materials used in lenses, prisms, and coatings can significantly affect optical clarity, brightness, and color accuracy.

Longevity: Durable materials contribute to the longevity of the binoculars, ensuring they remain a valuable hunting companion for years.

Chassis Materials

The chassis is the structural framework of binoculars, providing the foundation for the optical components. Two common materials are used in the construction of binocular chassis:

Magnesium Alloy:

Often found in high-end binoculars, magnesium alloy combines lightweight properties with impressive strength. It’s resistant to corrosion, making it an ideal choice for outdoor use. Hunters appreciate magnesium alloy binoculars for their durability without adding excessive weight to their gear.

Polycarbonate:

Budget-friendly binoculars may opt for polycarbonate chassis. While not as robust as magnesium alloy, polycarbonate is still lightweight and durable. It’s also impact-resistant, which can protect the internal components from shock.

Armor Coatings

The exterior of hunting binoculars is often coated with rubber armor or similar materials. This protective layer serves multiple purposes:

Grip and Impact Protection:

Rubber armor coatings provide a secure grip, ensuring that binoculars won’t slip from your hands, even in wet or cold conditions. Additionally, they act as shock absorbers, protecting the binoculars from minor impacts and falls.

Water Resistance:

Rubber armor coatings offer a level of water resistance, safeguarding the binoculars in damp environments. They help prevent moisture from seeping into the interior and affecting the optical components.

Scratch Resistance:

Some manufacturers go beyond standard rubber armor and apply proprietary coatings like Armortek. These coatings are designed to resist scratches and abrasions, enhancing the binoculars’ overall durability.

Lenses and Prisms

The quality and durability of lenses and prisms are pivotal for optical performance:

ED and HD Glass:

High-quality binoculars often feature lenses made from extra-low dispersion (ED) or high-definition (HD) glass. These specialized glass types not only deliver exceptional optical clarity but also resist scratches and damage.

Coatings:

Premium binoculars incorporate advanced coatings, such as phase coating and dielectric coating. These coatings improve image quality and protect prisms from environmental damage.

Weatherproofing

Hunting often means exposure to rain, snow, and rapidly changing temperatures. To address this, manufacturers employ two crucial features:

Waterproofing:

Binoculars are sealed with O-rings to make them waterproof. This prevents moisture from entering the optical chamber and causing internal fogging or damage.

Fog proofing:

Many high-quality binoculars are filled with inert gases like nitrogen or argon. This prevents internal fogging even in extreme temperature variations, ensuring clear vision in all conditions.

Hinges and Moving Parts

Durability isn’t just about materials; construction matters too. High-quality binoculars often feature metal hinges and moving parts designed to withstand frequent adjustments and usage without wearing down or breaking.

Lens and Eyepiece Caps

Even the most durable binoculars can suffer wear and tear over time if not adequately protected. Lens and eyepiece caps, typically made of durable materials like rubber or high-quality plastics, shield the most vulnerable parts of the binoculars from dust, debris, and impacts.

Warranty and Reputation

When looking for hunting binoculars, consider the reputation of the manufacturer. Reputable brands often offer longer warranties, reflecting their confidence in the durability of their products. Opting for a trusted brand can provide peace of mind, knowing that your investment is backed by a company with a history of producing reliable gear.

Frequently Asked Questions (FAQs)

Why is durability important in hunting binoculars?

Durability is essential because hunting binoculars are exposed to rugged outdoor conditions, including impacts, moisture, and temperature fluctuations. Durable materials ensure the binoculars can withstand these challenges and remain functional for years.

What are some common materials used in the construction of hunting binoculars?

Common materials include magnesium alloy and polycarbonate for chassis, rubber armor coatings for exterior protection, and high-quality glass like extra-low dispersion (ED) or high-definition (HD) glass for lenses.

Can all hunting binoculars withstand wet conditions?

No, not all binoculars are waterproof. It depends on the materials used and the design. Look for binoculars with effective seals and waterproofing features to ensure moisture resistance.

What should I do to maintain the durability of my hunting binoculars?

Proper maintenance includes keeping lens and eyepiece caps on when not in use, cleaning lenses with a microfiber cloth, and storing binoculars in a protective case. Avoid dropping or mishandling them to prevent damage.

Conclusion

The materials used in the construction of hunting binoculars are not mere details; they are the foundation of an optical instrument that can make or break a hunt.

From lightweight yet robust chassis materials to protective rubber armor coatings, advanced glass types, and weatherproofing features, every aspect contributes to the durability of these essential tools.

A Binoculars enthusiast, who love exploring skies and watching birds. It is my hobby to collect Binoculars of different kinds and try to explore the world through various lenses. This is all I do to explore happiness by magnifying my beautiful world.